The truck market is great in the sense that it takes no bullshit: cost is king. However, people are still trying to suggest a possible carbon-free alternative to diesel trucks. An electric semi-final doesn’t seem to be the answer. Their battery packs will degrade quickly with rapid charging, this process takes a long time, and they are much heavier than other trucks, which limits their payload capacity. According to Alexander Vlaskamp, fuel cell trucks also do not achieve the discount due to hydrogen prices.

44 photos

Photo: Nicola / Edited by Autoevolution

“Hydrogen is very expensive, almost four to five times what would be interesting for our customers to use. Therefore, hydrogen will only be used in a small segment in Europe, such as for private transport,” MAN’s CEO told the Austrian newspaper Der Standard. This will be the reason why MAN will bet on buses and trucks equipped with batteries. More context might help explain this.

MAN belongs to the Volkswagen Group, which is betting everything on battery electric vehicles (BEVs). Flaskamp even said the technology is “mature and more efficient.” Although the second part is true, the first is more controversial. Discussions about range, thermal runaway risks, swapping battery packs, and new cell technologies show that nothing is set in stone for battery electric vehicles, even if automakers like Tesla and Volkswagen would like us all to believe that is the case.

Photo: Nicola

However, any executive from the German automaker who said anything against battery electric cars and in favor of fuel cells should fear the pink slip. On the other hand, they will also avoid mentioning anything that is easy to deny or has no factual confirmation. However, hydrogen prices must be really high, making the transportation cost per mile more expensive than it should be. If transportation expenses are high, so are the prices of the products that must be transported.

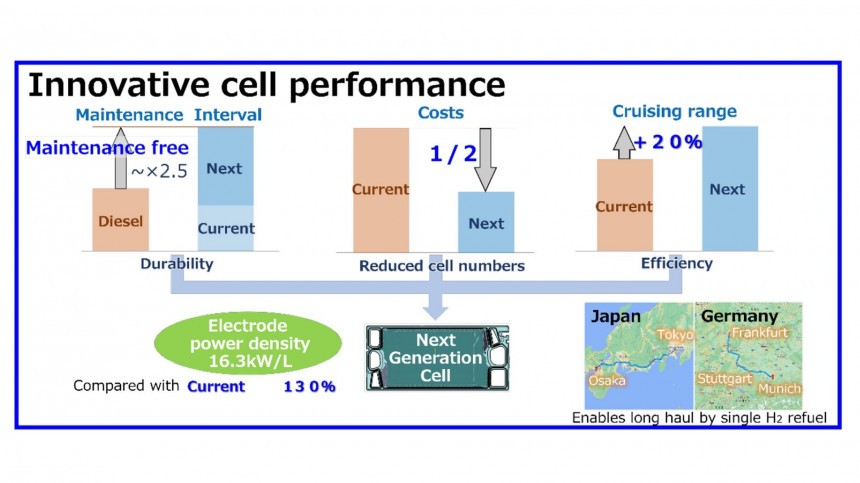

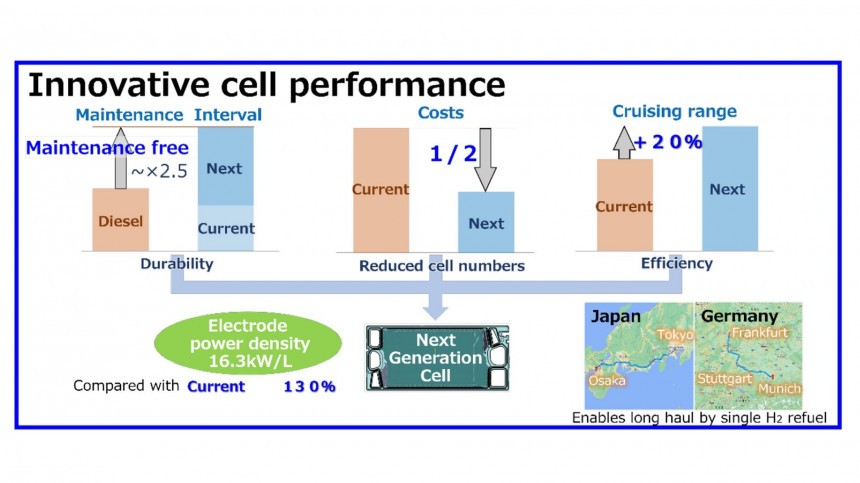

Anyone trying to manufacture and sell hydrogen fuel cell vehicles has to worry about two things: maintenance costs and refueling expenses. Toyota is aware of this and has already announced its own hydrogen plant to address the situation. Summing up its plans, it will deliver a fuel cell that requires repairs much later than a diesel engine would – at 2.5 times what a diesel engine does. ice Requires truck. However, a larger maintenance-free interval will not help if hydrogen prices are as high as Flaskamp mentioned at the moment. Toyota is working to reduce this by producing hydrogen.

Photo: Toyota

On June 26, the Japanese automaker announced that its first equipment to produce green hydrogen from chicken manure and food waste will be installed in Thailand in November 2023. The hydrogen will be extracted from biogas coming from these renewable sources. Toyota will also manufacture green hydrogen using renewable energy and electrolysis but will use fuel cell technology to do so. The Japanese automaker did not explain how fuel cells could help make electrolysis more efficient.

Assuming Toyota, Nikola and other companies that want to promote the use of hydrogen succeed, MAN’s CEO may have to revise the company’s plans due to more competitive operating costs. Meanwhile, Vlaskamp knows he’ll be working a lot more with the company’s battery-electric trucks. As he pointed out, it would be difficult to use them as refrigerated trucks or garbage trucks. They need power respectively to keep the storage room cool and compact the trash, which will reduce their range significantly.

Photo: Toyota

Another challenge will be shipping these trucks and buses quickly. European truck drivers are required to stop for 45 minutes every four hours for safety reasons. This would be the perfect moment to recharge their trucks, but the battery packs in these machines are much larger than those in battery-electric cars, which already take about 30 minutes for a quick charge. Another hitch is that fast charging doesn’t go all the way to 100% capacity, but only to 80%. This is a measure to save time and conserve battery pack. The resulting shorter range adds to other difficulties a battery-powered truck may face, such as cold weather and steep terrain with long climbs.

Vlaskamp estimates that Europe will need “more than 20,000 stations along major roads and motorways by 2030 in order to implement about 30 percent of logistics transport electrically.” Remember, they will not be stations for battery electric cars: they will have to be designed specifically for trucks, which “will cost several billion euros.” MAN’s CEO will also have to find a way to make these electric trucks cheaper. As he puts it, “E-trucks are much more expensive to buy than diesel vehicles today.” His argument is that it’s “much cheaper” to operate, which is only subtle, while the battery pack doesn’t have to be replaced. Try to see if anyone repeats this story that it will last as long as a truck, as battery electric cars do: no one would dare say that, at least with current cell technology.